Elevate Performance: Crucial Tips for Maintaining Undercarriage Parts Effectiveness

Elevate Performance: Crucial Tips for Maintaining Undercarriage Parts Effectiveness

Blog Article

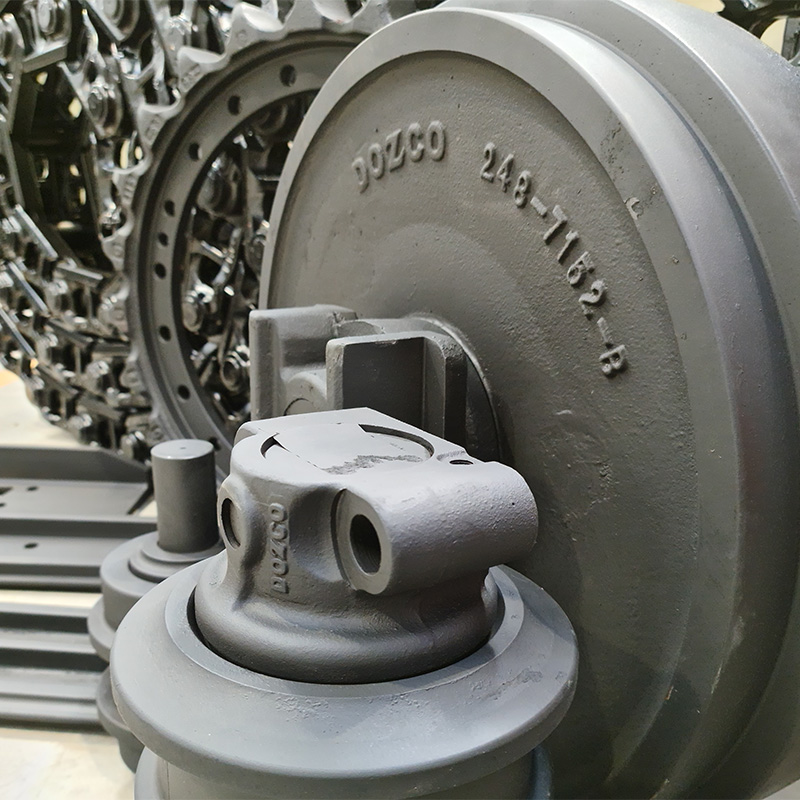

Discover Undercarriage Parts for Heavy Equipment

Understanding the ins and outs of undercarriage parts is crucial for the ideal efficiency and long life of hefty equipment. From track footwear to gears, rollers, and idlers, each part plays a crucial role in the performance of the devices.

Value of Undercarriage Parts

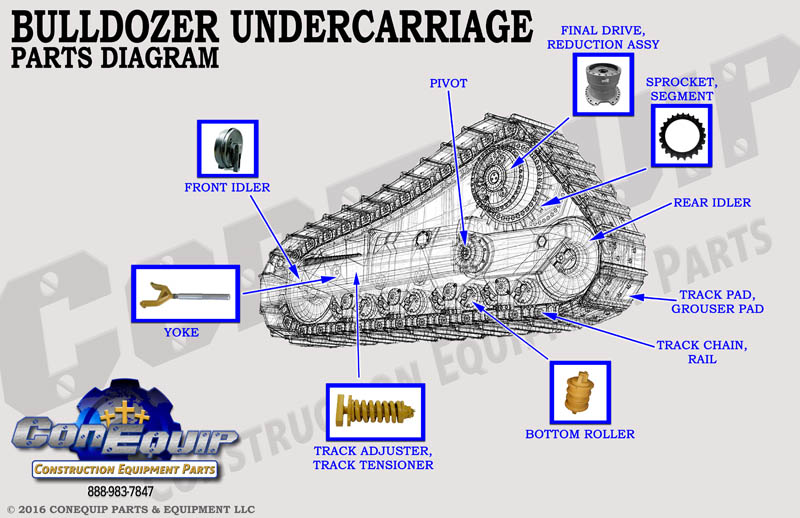

The undercarriage components of heavy equipment play an important role in making certain the general performance and long life of the tools. These elements, consisting of tracks, rollers, gears, chains, and idlers, form the foundation upon which the maker operates. A well-maintained undercarriage not only supplies stability and support to the hefty machinery yet additionally adds significantly to its operational effectiveness and performance.

Among the key advantages of buying high-quality undercarriage parts is the decrease of downtime and maintenance prices. By utilizing durable parts that can withstand the roughness of heavy-duty applications, drivers can minimize the requirement for frequent fixings and replacements, thus maximizing the equipment's uptime and total life-span.

Additionally, correctly working undercarriage parts make certain optimal weight circulation, grip, and ability to move, allowing the heavy machinery to operate efficiently also in challenging terrains. This dependability is important for sectors such as farming, mining, and construction, where tools efficiency directly influences project timelines and profitability. To conclude, the value of undercarriage components can not be overstated in preserving the efficiency and durability of heavy equipment.

Kinds Of Track Shoes

When considering the numerous kinds of track footwear for heavy equipment, it is important to review their style and performance in regard to specific functional demands. Track shoes are critical parts of the undercarriage system, giving traction, security, and weight circulation for heavy machinery such as excavators, excavators, and spider cranes.

One of the most typical types of track shoes consist of:

** Grouser Shoes **: Including increased steel bars (grousers) along the shoe's surface, these track footwear offer improved traction in challenging surfaces like mud, snow, and loosened gravel. undercarriage parts.

** Dual Grouser Shoes **: Comparable to grouser footwear yet with an additional collection of grousers, these track shoes use even better traction and security, making them optimal for extremely rough terrains.

** Triple Grouser Shoes **: With three collections of grousers, these track shoes provide maximum traction and stability, making them suitable for the most demanding conditions.

Selecting the best sort of track footwear is important for optimizing the efficiency and long life of hefty machinery while making certain safety and effectiveness during procedures.

Function of Rollers and Idlers

Rollers and idlers play indispensable roles in supporting and leading the track shoes of heavy machinery during operation. By preventing too much slack or rigidity in the tracks, idlers contribute to the total stability and performance of the machinery.

In addition, rollers and idlers interact to keep the track shoes abreast, avoiding them from thwarting or sliding off throughout procedure. Effectively functioning idlers and rollers are important for guaranteeing the long life of the undercarriage system and making the most of the machine's effectiveness. Routine upkeep and evaluation of these elements are important to determine any signs of wear or damage beforehand, avoiding expensive repair work and downtime in the long run.

Role of Sprockets in Equipment

Upkeep Tips for Undercarriage Parts

Efficient maintenance of undercarriage elements is important for making sure the longevity and optimal performance of heavy machinery. Routine evaluation of undercarriage parts such as track chains, rollers, idlers, sprockets, and track footwear is critical to stop unanticipated break downs and expensive repair services. One key upkeep idea is to keep the undercarriage tidy from debris, mud, and other impurities that can speed up wear and deterioration. It is additionally crucial to ensure appropriate track stress to stop premature endure components. Oiling the undercarriage components at advised periods aids to decrease rubbing and expand the life-span of the components. Keeping track of for any type of unusual noises, resonances, or adjustments in device efficiency can suggest potential problems with the undercarriage that require instant interest. more information By following these maintenance pointers vigilantly, hefty equipment drivers can minimize downtime, decrease operating prices, and make best use of the performance of their devices.

Conclusion

Finally, the undercarriage parts of hefty machinery play a vital role in ensuring the smooth performance and durability of the tools. Recognizing the importance of track footwear, rollers, idlers, and gears, along with applying appropriate maintenance practices, can greatly affect the total performance and performance of the machinery (undercarriage parts). Normal assessment and prompt replacement of worn-out components are important in optimizing the lifespan and productivity of hefty machinery

Rollers and idlers play important roles in supporting and assisting the track footwear of hefty machinery throughout procedure.In hefty machinery, sprockets offer a crucial function in transferring power from the engine to the tracks, making it possible for the equipment to move her latest blog successfully and properly. These components are connected to the axles or final drives of the machinery and job in conjunction with the tracks to thrust the tools forward or backward. Regular evaluation of undercarriage components such as track chains, rollers, idlers, sprockets, and track shoes is essential to avoid pricey fixings and unanticipated failures. Comprehending the value of track footwear, gears, idlers, and rollers, as well as executing appropriate maintenance practices, can significantly impact the total efficiency and performance of the machinery.

Report this page